Telwin THUNDER 304 CE KOHLER 825002 Generator – Instrukcja obsługi w formacie pdf, czytaj online za darmo. Mamy nadzieję, że okaże się ona pomocna w przypadku jakichkolwiek pytań związanych z użytkowaniem urządzenia.

Jeśli nadal masz wątpliwości, zadaj pytanie w komentarzach pod instrukcją.

"Ładowanie instrukcji" oznacza, że musisz poczekać na pobranie pliku, aby móc go przeczytać online. Niektóre instrukcje są bardzo obszerne, a czas ich ładowania zależy od szybkości łącza internetowego.

- 8 -

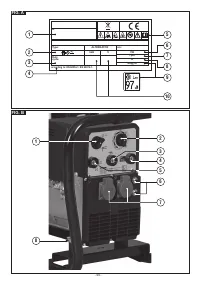

- Connect the tool outlet to the input on the machine (Fig. B-7 or C-7,

C-8).

- Move the selector to position

230V 1~

(Fig. B-1) (200A AC

VERSION only).

WARNING!

- The load must be applied when the engine has been started.

- Disconnect the load before switching off the engine.

- If the AC outlets are overloaded or if the connected equipment

malfunctions, the thermostatic safeguards cut in (Fig. B-6 or C-6).

- Reset is not automatic. To reset the system (RESET) the

thermostatic safeguard MUST be re-activated.

- With the 200A AC version, the machine cannot be used as a

welding machine and a generator at the same time.

- With the 300A DC version it is advisable not to use the machine as

a welding machine and a generator at the same time (the output

voltage would not be constant).

It is forbidden and dangerous to connect the machine

and power the electric network of a building.

8. MAINTENANCE

WARNING! BEFORE CARRYING OUT MAINTENANCE,

MAKE SURE THE ENGINE-DRIVEN WELDING MACHINE IS

SWITCHED OFF.

ROUTINE MAINTENANCE

ROUTINE MAINTENANCE WORK CAN BE DONE BY THE

OPERATOR.

INTERNAL COMBUSTION ENGINE MAINTENANCE

Carry out the checks and programmed maintenance indicated in

the USER MANUAL of the internal combustion engine producer.

EXTRAORDINARY MAINTENANCE

EXTRAORDINARY MAINTENANCE MUST ONLY BE CARRIED

OUT BY TECHNICIANS WHO ARE EXPERT OR QUALIFIED IN

THE ELECTRIC-MECHANICAL FIELD, AND IN FULL RESPECT

OF THE IEC/EN 60974-4 TECHNICAL DIRECTIVE.

WARNING! BEFORE REMOVING THE ENGINE-DRIVEN

WELDING MACHINE PANELS AND ACCESSING IT, MAKE SURE

IT IS SWITCHED OFF.

If checks are carried out while the inside of the engine-driven

welding machine is live this could cause serious electric shock

due to direct contact with live parts and/or injury due to direct

contact with moving parts.

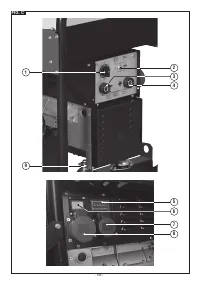

- Make regular checks, at intervals that depend on the use and on

the amount of dust in the environment, inspecting the inside of the

engine-driven welding machine and removing any dust deposited

on the alternator and on the reactance coil using a jet of dry

compressed air (max. 10bar).

- Take the opportunity to make sure there are no loose electrical

connections and that the wiring insulation has not been damaged.

- After completing these operations, re-assemble the engine-driven

welding machine panels, fastening down the screws tightly.

- Never ever carry out welding operations if the engine-driven

welding machine is open.

- After having carried out maintenance or repairs, restore the

connections and wiring as they were before, making sure they do

not come into contact with moving parts or parts that can reach high

temperatures. Tie all the wires as they were before, being careful

to keep the high voltage connections of the primary transformer

separate from the low voltage ones of the secondary transformer.

Use all the original washers and screws when closing the casing.

- Periodically check the brushes for wear and position (300A DC

VERSION only).

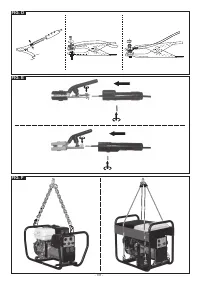

9. ENGINE-DRIVEN WELDING MACHINE TRANSPORT AND

WINTER STORAGE

Regarding engine-driven welding machine transport and winter

maintenance, refer to the USER MANUAL of the internal combustion

engine producer.

10. TROUBLESHOOTING

IF THE MACHINE IS NOT WORKING PROPERLY, BEFORE

MAKING MORE SYSTEMATIC CHECKS OR CALLING YOUR

SERVICING CENTRE MAKE THE FOLLOWING CHECKS:

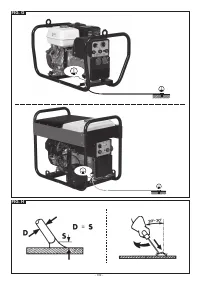

- The welding current is suitable for the diameter and type of

electrode to be used.

- Make sure you have not exceeded the rated duty cycle; if the

thermal relay has triggered wait until the engine-driven welding

machine has cooled naturally, make sure the fan is working

properly.

- Make sure there is no shorting at engine-driven welding machine

output: in such a case eliminate the problem.

- Make sure the welding circuit connections have been made

correctly, in particular that the earth clamp is actually connected to

the piece, with no insulating material (e.g. paint) in the way.

As far as troubleshooting for the engine is concerned, refer to

the USER MANUAL of the internal combustion engine producer.

Refer to the nearest internal combustion engine retailer should

problems with the engine occur.

I

MANUALE ISTRUZIONE

ATTENZIONE! PRIMA DI UTILIZZARE LA MOTOSALDATRICE

LEGGERE ATTENTAMENTE IL MANUALE DI ISTRUZIONE

DELLA MOTOSALDATRICE E QUELLO DEL MOTORE A

SCOPPIO. NON FACENDOLO SI POTREBBERO CAUSARE

FERITE A PERSONE O DANNI A IMPIANTI, APPARECCHIATURE

O ALLA MOTOSALDATRICE STESSA.

MOTOSALDATRICI PER LA SALDATURA MMA PER USO

INDUSTRIALE E PROFESSIONALE.

Nota: Nel testo che segue verrà impiegato il termine “motosaldatrice”.

1. NORME DI SICUREZZA GENERALI

- Controllare il motore prima di ogni uso (vedi il manuale del

costruttore del motore a scoppio).

- Non collocare oggetti infiammabili vicino al motore e tenere

la motosaldatrice ad almeno 1 metro da edifici e da altre

attrezzature.

- Non utilizzare la motosaldatrice in ambienti con pericolo

di esposione e/o incendio, in locali chiusi, in presenza di

liquidi, gas, polveri, vapori, acidi ed elementi infiammabili e/o

esplosivi.

- Rifornire il motore di carburante in un’area ben ventilata e

da fermo. La benzina è altamente infiammabile e può anche

esplodere.

- Non riempire troppo il serbatoio del carburante. Nel collo del

serbatoio non ci deve essere carburante. Controllare che il

tappo sia ben chiuso.

- Se si versa del carburante fuori del serbatoio, pulirlo bene

e permettere ai vapori di dissiparsi prima di accendere il

motore.

- Non fumare e non portare fiamme non protette nel luogo

dove il motore viene rifornito di carburante o la benzina viene

conservata.

- Non toccare il motore quando è caldo. Per evitare gravi

ustioni o incendi prima di traportare o immagazzinare la

motosaldatrice lasciare che il motore si raffreddi.

- I gas di scarico contengono monossido di carbonio, gas

velenosissimo, inodore ed incolore. Evitarne l’inalazione. Non

far funzionare la motosaldatrice in luoghi chiusi.

Nadal masz pytania?Nie znalazłeś odpowiedzi w instrukcji lub masz inne problemy? Zadaj pytanie w poniższym formularzu i opisz szczegółowo swoją sytuację, aby inni użytkownicy i eksperci mogli udzielić ci odpowiedzi. Jeśli wiesz, jak rozwiązać problem innej osoby, podziel się swoją wiedzą :)